Three-row cylindrical roller slewing bearing with External gear

category:Slewing bearing

| Parameter name | Parameter value |

|---|---|

| material | 42CrMo 50Mn |

| Accuracy class | P0、P6、P5 |

| Hardness of quenching and tempering | 229~269HB/ customizable |

| Raceway hardness | 58~64HRC |

| Production cycle | 30~60 days |

Consultation hotline:185-3836-8720

Three-row cylindrical roller slewing bearing with External gear

category:Slewing bearing

| Parameter name | Parameter value |

|---|---|

| material | 42CrMo 50Mn |

| Accuracy class | P0、P6、P5 |

| Hardness of quenching and tempering | 229~269HB/ customizable |

| Raceway hardness | 58~64HRC |

| Production cycle | 30~60 days |

Consultation hotline:185-3836-8720

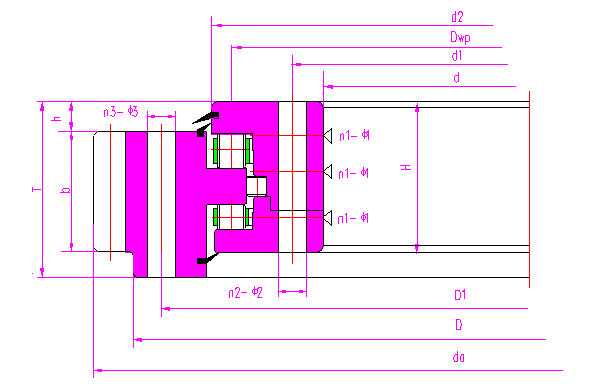

Three-row cylindrical roller combined slewing bearing (slewing ring) bears axial load, overturning moment and radial load at the same time. Compared with the crossed cylindrical roller slewing bearing, the load of each roller is reduced. Compared with the double-row different diameter ball slewing bearing, the point contact is changed to the line contact, which reduces the contact stress. Therefore, under the same external dimensions Bearing capacity is higher. The axial load and radial load of the structure are respectively borne by different rollers, in which the axial load and overturning moment are borne by two sets of rollers placed horizontally on the axis, and the radial load is borne by a set of rollers placed vertically on the axis.

Three-row cylindrical roller combined slewing bearing (slewing ring) is mainly composed of inner ring, outer ring, three-row rollers, cage (isolation block), sealing device and other parts.

1. The materials of inner ring and outer ring are generally 42CrMo, 50Mn, 45# steel and other materials. The inner ring and outer ring generally have a quenched and tempered hardness between 170HB-340HB. According to the conditions of use, different quenched and tempered hardness ranges can be selected for the ferrule hardness. Under normal circumstances, the quenched and tempered hardness of the ferrule is 229-269HB, and the wind turbine is yaw The quenching and tempering hardness of the pitch bearing ring is 270-320HB. The quenching hardness of the raceway is generally 55-62HRC. The tooth quenching hardness is generally 50±5HRC, and the tooth accuracy reaches 7 or above, and the tooth needs to be ground.

2. The rolling elements are generally selected from GCr15 or GCr15SiMn bearing steel, and the materials can be selected from bars or forgings, which are mainly determined according to the working conditions and the size of the rolling elements. The hardness of the rolling element is generally 58-62HRC, and the roller can be selected with a convexity grade 2 rolling element.

3. The material of the cage (isolation block) is generally nylon PA66, but also steel, brass, aluminum alloy and other materials.

4. Generally, nitrile butadiene rubber and fluorine rubber are used as the sealing material, and it can be decided whether to install a labyrinth dust guard according to the needs.

5. Surface treatment, generally use lubricating oil to prevent rust. According to the usage, the surface can be treated with anti-corrosion. At present, the surface treatment methods of slewing bearings include phosphating, zinc spraying and paint spraying.

The three-row cylindrical roller slewing bearing (slewing ring) structure bearing is suitable for occasions with large axial load and overturning moment, large radial load, and low friction moment.

扫一扫

扫一扫